A belling machine, also known as a pipe belling machine or pipe socketing machine, is essential in the manufacturing process for socketing of plastic pipes. It enlarges the pipe end to create a socket for a joint with another pipe. When considering a belling machine for your production line, here are some key features and considerations to look for:

Compatibility with Pipe Materials and Sizes:

Ensure the machine is compatible with the types of plastics (PVC, PP, etc.) and the range of pipe diameters and lengths you plan to produce. Some machines offer versatility to handle various materials and sizes, while others are more specialized.

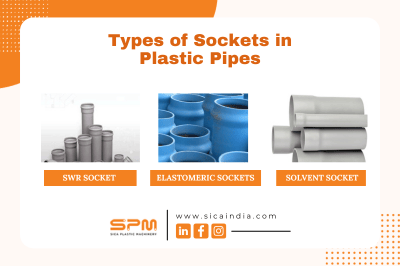

Type of Belling Process:

Belling machines can use different methods set of tools to shape the pipe end, such as solvent cement sockets , swr sockets, elastomeric sockets. Each type of socket has its benefits and applications, so choose based on your specific needs.

Automation Level:

Consider the degree of automation provided. Automated machines can increase production efficiency, ensure consistent quality, and reduce labor costs. Semi-automatic and fully automatic machines are available, with varying levels of control and automation features.

Production Speed and Efficiency:

Assess the machine’s production capacity to ensure it meets your output requirements. Check the cycle time for belling and the ease of changing sizes and types, as these factors directly impact productivity.

Quality and Precision:

Look for machines that offer high-quality and precise belling. This includes uniform heating, precise expansion, and consistent cooling to ensure the dimensional accuracy of the bell end.

Ease of Operation and Maintenance:

User-friendly interface, easy setup, and straightforward maintenance are important for operational efficiency. Look for machines with accessible parts, clear instructions, and reliable customer support.

Durability and Reliability:

The construction quality of the machine affects its longevity and reliability. Choose a belling machine built with high-quality materials and components to minimize downtime and maintenance costs.

Safety Features:

Ensure that the socketing machine has adequate safety features to protect operators, such as guards, emergency stops, and safety interlocks.

Energy Efficiency:

Consider the energy consumption of the machine, as this will impact operating costs. Look for energy-efficient designs and features that reduce power usage without compromising performance.

Cost-Effectiveness:

Evaluate the total cost of ownership, including purchase price, operating costs, maintenance, and potential downtime. A machine that initially seems expensive may offer savings in the long run through efficiency, durability, and lower maintenance costs.

After-Sales Support:

Good after-sales support is crucial for resolving issues and maintaining the machine. Check for warranty terms, availability of spare parts, and access to technical support.

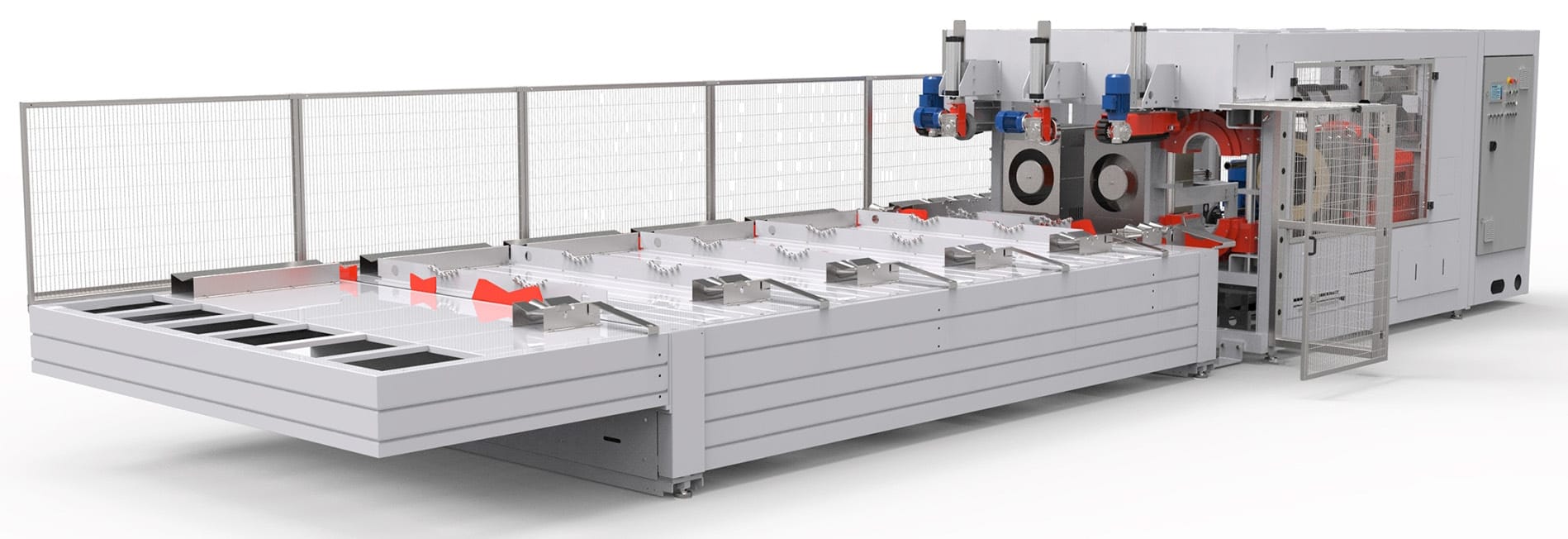

FASTFORM emerges as the perfect choice if you are in the market looking for a belling machine for plastic pipe manufacturing processes. Its compatibility with various pipe materials and sizes, coupled with a range of belling processes including solvent cement sockets, SWR sockets, and elastomeric sockets, ensures versatility to meet diverse production needs.

The fully automatic design of FASTFORM not only boosts production efficiency but also guarantees consistent quality while reducing labor costs. With a remarkable output capacity of up to 400 sockets per hour, FASTFORM excels in delivering exceptional productivity. Its precision engineering ensures high-quality and precise belling, supported by user-friendly operation and maintenance features for enhanced operational efficiency.

Moreover, FASTFORM’s durability, reliability, energy efficiency, and cost-effectiveness make it a strategic long-term investment for businesses aiming to stay ahead in the competitive market. The machine’s emphasis on safety features and robust after-sales support further solidifies its position as the top choice for achieving perfect socket shapes consistently and delivering superior products in the industry.