Sockets are a crucial component in connecting plastic pipes, ensuring a secure and leak-free joint. Different types of sockets serve specific purposes and offer varying levels of strength, flexibility, and ease of installation.

Here’s a look at some of the most common types of sockets in plastic pipes:

1. SWR Socket Ring Type :

SWR stands for “Soil, Waste, and Rainwater.” These sockets are designed for drainage systems and have a smooth inner surface for efficient water flow.

2. Elastomeric Sockets:

Elastomeric sockets are flexible and provide excellent vibration damping and noise reduction. They are commonly used in hot and cold water supply lines. These sockets often feature an O-ring seal for added leak protection and can be installed using a solvent cement or mechanical crimping method.

Similar to elastomeric sockets, O-ring sockets utilize a rubber O-ring for a secure and leak-free connection. They offer high pressure resistance and are suitable for various applications, including water supply lines, irrigation systems.

3. Solvent Socket:

Solvent sockets are the most traditional type of socket and rely on solvent cement for jointing. They are simple to install and offer a strong and durable connection.

Introducing FASTFORM by SICA India:

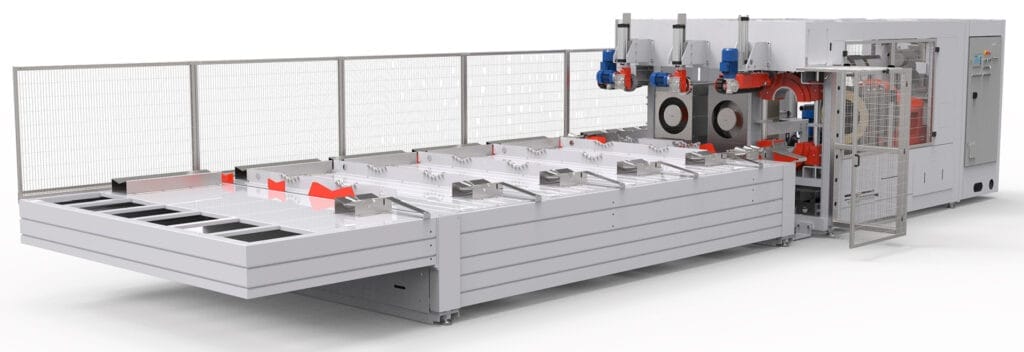

FASTFORM is a fully automatic inline belling machine from SICA India, specifically designed for high-volume socketing needs. It boasts several features that make it a top choice for industries requiring efficiency and accuracy:

Features:

- Dual Oven: Enables processing of Solvent cement , Elastomeric sockets and SWR Sockets in same machine . Double Ovens for efficient heating all around pipes with rotation of pipes. (Available on Select Models only)

- Heating and Cooling Cycles: Ensures optimal material properties for forming of socket.

- Accuracy and Precision: Produces consistent and high-quality sockets.

- High Production Capacity: Delivers efficient and rapid socketing process.

- Optional Collection Table: Accommodates pipes collection from Dual Extrusion lines and feeding it to Belling machine one pipe at a time.

Benefits:

- Increased Production Efficiency: FASTFORM’s automated nature significantly reduces production time compared to manual socketing process.

- Improved Quality Control: Precise temperature control and consistent heating and cooling cycles ensure the creation of high-quality sockets.

- Reduced Labor Costs: Automation minimizes manual labor requirements, leading to cost savings.

- Versatility: Handles both solvent cement and elastomeric sockets, catering to various applications.

- Energy Efficient: Extremely low energy cost per socket.

Overall, FASTFORM presents a comprehensive solution for high-volume socketing needs. Its combination of innovative features, high production capacity, and versatility makes it an ideal choice for industries seeking efficiency, accuracy, and quality in socket production.